In an era when sustainability is more than just a fad, industrial waste management stands out as a critical aspect of modern business practices. Effective industrial waste management not only mitigates harmful environmental impacts but also optimises operational efficiency and improves corporate reputation. Understanding and implementing best practices in this area is, therefore, essential for businesses across all sectors. This blog explores these practices, providing a clear guide to managing industrial waste effectively.

Understanding Industrial Waste

Industrial waste encompasses a wide range of materials produced as byproducts of industrial activities, including chemicals, metals, paper, and more. It differs from municipal waste due to its composition and the scale on which it is produced. Managing this waste responsibly is crucial due to its potential impact on the environment and human health.

The Importance of Proper Management

Proper industrial waste management is not merely a legal obligation; it’s a moral and environmental imperative. Effective management aligns with global efforts to achieve sustainability and environmental stewardship.

- Pollution Prevention: Proper industrial waste management systems help prevent the release of harmful substances into the environment. This includes managing airborne emissions, liquid effluents, and solid wastes, significantly reducing potential harm to ecosystems and human health.

- Resource Conservation: Through strategies such as the benefits of waste separation and recycling, valuable materials are recovered and reused, raw materials are conserved, and the demand for natural resources is reduced.

- Reducing Ecological Footprint: Industries can reduce their overall environmental impact by implementing sustainable waste management practices. This includes using less energy and fewer resources through efficient waste management processes.

- Compliance and Beyond While meeting legal standards is fundamental, going beyond compliance can enhance a company’s reputation and align its operations with global sustainability goals.

- Role of Technology in Waste Management: Advanced technologies enhance industrial waste management. Innovations such as automation in waste sorting, advanced waste oil disposal techniques, and using AI to optimise waste processing routes contribute significantly to more efficient and less environmentally impactful waste management.

- Economic Benefits: Efficient waste management can also lead to significant savings for businesses by reducing waste treatment costs and recovering value from waste materials.

Best Practices for Managing Industrial Waste

Industrial waste management is a critical component of sustainable business practices. It involves a series of strategic actions to minimise the environmental impact of waste generated from industrial operations. Here, we explore five key best practices businesses can adopt to enhance their waste management processes.

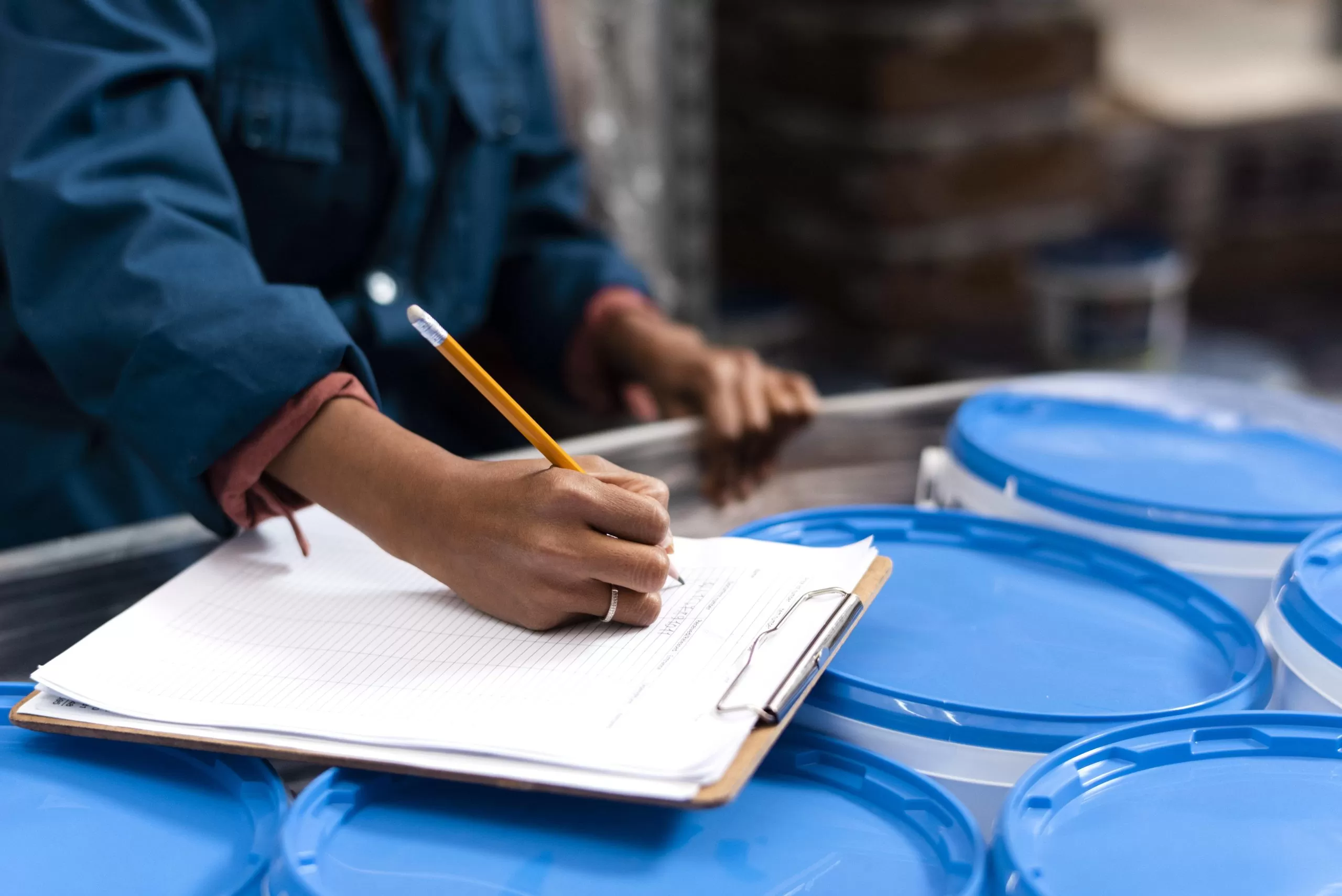

Conduct a Waste Audit

A waste audit is a fundamental step in effective industrial waste management. It involves a detailed assessment of the waste a company generates, serving as a basis for improving waste management strategies. Here’s how to conduct a waste audit:

- Identify: Catalogue every type of waste that your facility produces. This includes everything from paper and plastic to more complex waste like chemicals and metals.

- Quantity: Measure the amount of each type of waste generated over a specific period. This helps in understanding the scale of waste production.

- Analyse: Determine the sources of waste within your operations. Pinpointing whether waste comes from manufacturing, packaging, or administrative activities can help identify reduction strategies.

Prioritise Waste Reduction

Reducing the amount of waste generated at the source is the most effective way to manage industrial waste. This can be achieved through:

- Process Optimisation: Modify production processes to decrease waste output. This might involve updating or replacing outdated machinery that is less efficient and more wasteful.

- Material Substitution: Replace raw materials with more sustainable or less wasteful alternatives.

- Efficiency Training: Educate employees on new procedures and technologies to minimise waste. Their daily operations significantly affect overall waste production.

Segregation and Separation

The benefits of waste separation are immense in industrial waste management. Effective segregation facilitates recycling and reduces the volume of waste sent to landfills. Implementing separation involves:

- Designated Bins: Install separate bins for different types of waste, such as organic, recyclable, non-recyclable, and hazardous waste.

- Clear Labelling: Each bin should have clear, understandable labels that indicate what type of waste it should contain.

- Employee Training: Regular training sessions should be conducted to educate staff on the importance of correct waste segregation and the benefits of waste separation.

Implement Safe Storage and Handling Procedures

Safe storage and handling industrial waste are vital to prevent accidents and limit environmental harm. Best practices in storage and handling include:

- Appropriate Containers: Use containers suitable for the type of waste stored, especially for hazardous waste. Containers should be robust, leak-proof, and designed to prevent spillage.

- Regular Inspections: Conduct frequent inspections of waste storage areas to ensure they are secure and that all procedures are followed.

- Emergency Plans: Establish clear, well-practised emergency procedures for dealing with accidental spillages or leaks, particularly of dangerous materials.

Partner with Certified Waste Management Providers

For aspects of waste management, such as waste oil disposal and treatment of hazardous materials, partnering with certified waste management providers is crucial. These providers ensure that waste is treated and disposed of by legal and environmental standards. Consider the following when choosing a provider:

- Certifications and Compliance: Ensure the provider has all necessary certifications and complies with national and international waste management regulations.

- Technology and Methods: Evaluate the provider’s technology and methods. Technology plays a significant role in waste management, and advanced techniques often allow for better waste treatment and recovery.

- Reputation and Reliability: Choose providers known for their reliability and good practices. Providers should have a track record of compliant and responsible waste management.

Conclusion

Effective industrial waste management is a complex but achievable goal. Businesses can manage their waste more efficiently and sustainably by conducting thorough waste audits, prioritising reduction, ensuring effective segregation, and partnering with reputable providers. Implementing these practices helps comply with regulations and plays a crucial role in protecting the environment and supporting corporate sustainability goals.

Ready to transform how you manage waste? Connect with Benzoil today! As specialists in turning waste into valuable products, we’re dedicated to innovative and sustainable waste solutions. From procuring and marketing hydrocarbon products to transforming waste materials, Benzoil is your partner in redefining waste management.

FAQs

What are the key challenges in managing industrial waste?

The main challenges include:

- High costs

- Ensuring proper segregation

- Dealing with hazardous materials

- Staying compliant with evolving regulations

How can businesses reduce their environmental impact through waste management?

Businesses can reduce their impact by implementing reduction practices, recycling and reusing materials, and using environmentally friendly waste disposal methods.

What role do technology and innovation play in industrial waste management?

Technology and innovation are pivotal in improving industrial waste management by developing more efficient recycling techniques, better waste treatment technologies, and advanced materials that are easier to recycle.