Background

GrainOut is a subsidiary of Benzoil that specialises in food and beverage by-products.

GrainOut is pursuing alternate applications for peanut shells currently going to landfill.

Processing

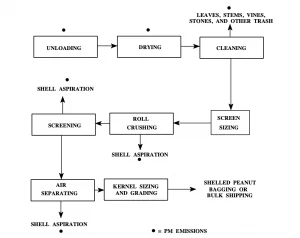

Peanut shells are a by-product from the processing of shelled peanuts (see figure 1). In Australia, the peanut shells are currently a waste stream and disposed after processing.

Figure 1 – Typical shelled processing flow diagram (Source: U.S. Environmental Protection Agency)

Alternate Applications for Peanut Shells

Despite peanut shells’ seemingly lack of value, it has surprisingly optimal characteristics as an absorbent.

Adsorbent of Uranium, Cadmium, Phenol & Oil in Water

A study by (Wei, Chen, & Jin, 2018) has shown peanut shells have been successfully grafted with quaternary ammine groups on its surface by using amination modification. The high sorption efficiency and eco-friendliness of amine cross linked peanut shell presented promising potential in radioactive pollution management of uranium from nuclear and weapon manufacturing (Wei, Chen, & Jin, 2018).

Another study analysed the removal of phenol and cadmium using activated carbon obtained from peanut shells (Villar da Gama, et al., 2018). Industrial effluents from refineries, chemical, paper and cellulose industries, among others, frequently contain concentrations of phenolic compounds and heavy metals, such as cadmium, cobalt and chromium (Villar da Gama, et al., 2018). The activated carbon analysed was considered a good adsorbent for the removal of phenol and cadmium, as it is derived from a renewable residue, thus contributing to more environmentally friendly processes (Villar da Gama, et al., 2018).

Developing a feasible and eco-friendly separation layer for the purification of emulsified oily wastewater is urgently needed and remains a great challenge (Zhao, Ren, Du, & et al, 2020). In a recent study, a biodegradable and superwettable separation layer was developed based on waste peanut shell via a facile method of mechanical grinding. The results exhibited a high separation efficiency (>99.5%) for disposing of a surfactant stabilized water-in-oil emulsion (Zhao, Ren, Du, & et al, 2020). Moreover, this layer maintained stable reusability after 55 cyclic operations. This successful creation of a peanut shell separation layer might provide new insights into the design of biomaterial separation layers for oily wastewater purification and resource utilization of agricultural residue (Zhao, Ren, Du, & et al, 2020).

PVA Biocomposites

In addition, further studies on PVA biocomposites prepared from peanut shell showed high mechanical and thermal properties. Cellulose nanofibers were isolated from peanut shell and exhibited mechanical properties as a reinforcing material for PVA (Wang & Li, 2015).

Biofuel and Biochar

The burning properties of peanut shells were assessed and the results showed that these residues are technically feasible power plant fuels to burn alongside coal or as a renewable biofuel on their own (Saeed, Andrews, Phylaktou, & Gibbs, 2017). Alternatively, thermal conversion of peanut shells to biochar has received increasing attention due to its renewability, easy availability and efficient use of wastes (Liu, Liu, Yousaf, & Abbas, 2018).

Bibliography available on request.

Whether peanut shells are used as an adsorbent to clean up industrial effluent, a biocomposite, biofuel or biochar, recent studies undertaken provide an operational framework on how to upcycle this waste stream into a valuable resource.

If GrainOut can assist with alternate applications for food manufacturing waste, please contact us on 0437 965 270.